Construction-Driven Planning Through Advanced Work Packaging

Some firms prefer to use Advanced Work Packaging (AWP) processes to ensure the success of their projects.

What is Advanced Work Packaging?

Advanced Work Packaging aligns teams in the early phases of a project to determine the optimal project execution strategy. AWP provides clarity on sequencing to create a path of construction used to guide activity and deliverables throughout the project lifecycle. Work gets divided into buckets for distinct phases within the project.

The key to success with AWP is that it is designed collaboratively by the engineering, procurement, and construction personnel to coordinate the project in a way that supports orderly system turnover, start-up, and commissioning. AWP clarifies and streamlines work needs by categorizing and organizing work details and scopes for individual departments, teams, and disciplines on the project.

Benefits of AWP

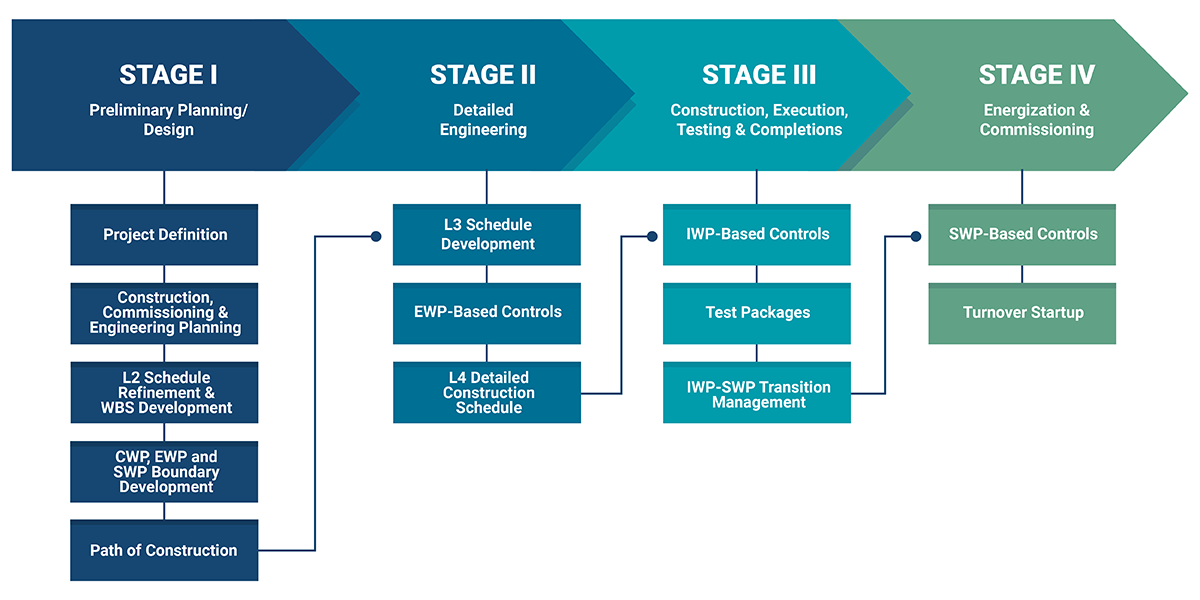

Integrating AWP early within the concept planning and engineering stages and utilizing it throughout the project lifecycle can assist in mitigating common construction challenges such as inefficiency, budget overages, and delayed deliverables by ensuring proper manpower, information, and materials. The process is construction-driven, adopting the philosophy of beginning with the end in mind. To learn about the various stages within the AWP Process, refer to Figure 1.

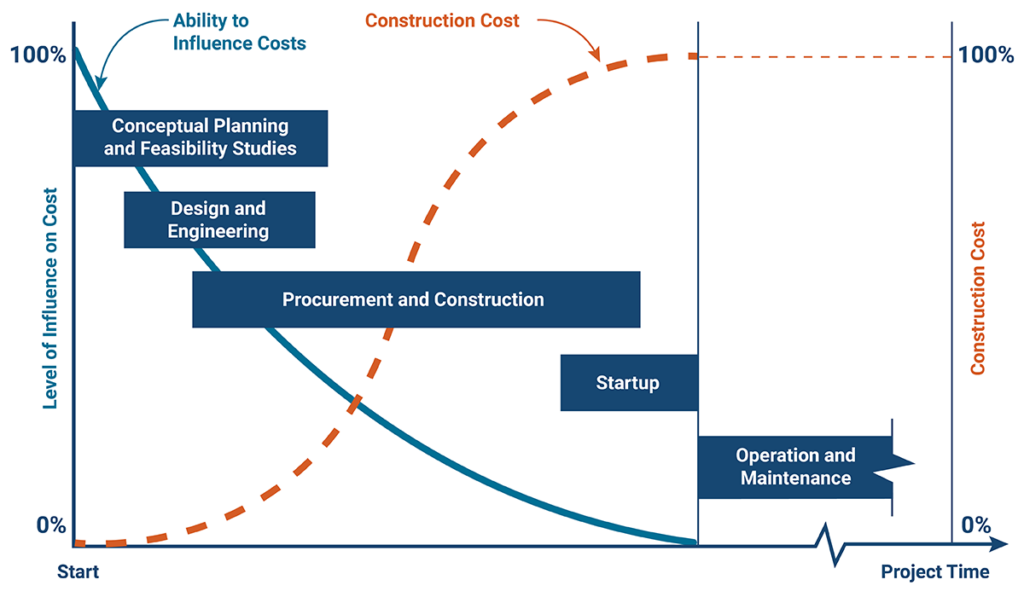

This technique offers the opportunity to influence cost, see Figure 2, and provides work clarity. In addition, this technique utilizes proper material management, which reduces the need for excessive Request for Information Orders and Extra Work Orders.

Projects That Omit Advanced Work Packaging

Projects that do not employ construction planning services or prepare an AWP plan face obstacles such as information silos and preparation failure. Without detailed coordination of engineering and procurement support, projects suffer from inefficient execution. This can place a large burden on the field supervisor to conduct routine execution planning.

Projects reviewed by our firm without the implementation of AWP often face engineering errors and significant schedule and cost impacts. Oftentimes, contractors in this scenario do not establish or enforce sequential construction paths, which negatively affects the sequencing of construction and procurement work packages. For example, considerations for construction-enhancing features may be excluded from project engineering, due to poor planning.

Leverage Our Expertise

Construction planning, construction management, and project controls are essential to running a smooth and profitable project. Our expertise in preconstruction management, constructability, procurement, pull planning, baseline scheduling, and cost management can guide projects to become more adaptable and agile.

Contact us if your construction project needs assistance identifying solutions, mitigating uncertainty, and keeping deliverables on track for success.